Microsoft PowerPoint - I - CETA 2020 critical minerals innovation.pptx

Dieses Dokument ist Teil der Anfrage „Documents on CETA: Bilateral Dialogue on Raw Materials“

Ref. Ares(2021)6044578 - 05/10/2021 Advancing Canada’s Critical Minerals Agenda: Innovation in Primary and Circular Recovery November 17, 2020 CanmetMINING, NRCan

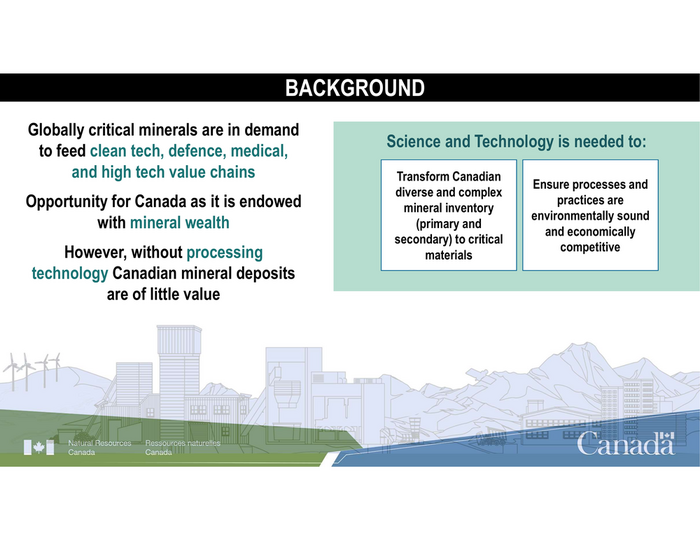

BACKGROUND DRIVERS DRAFT DRAFT 2 Globally critical minerals are in demand Science and Technology is needed to: to feed clean tech, defence, medical, and high tech value chains Transform Canadian Ensure processes and diverse and complex Opportunity for Canada as it is endowed mineral inventory practices are environmentally sound with mineral wealth (primary and and economically secondary) to critical However, without processing competitive materials technology Canadian mineral deposits are of little value

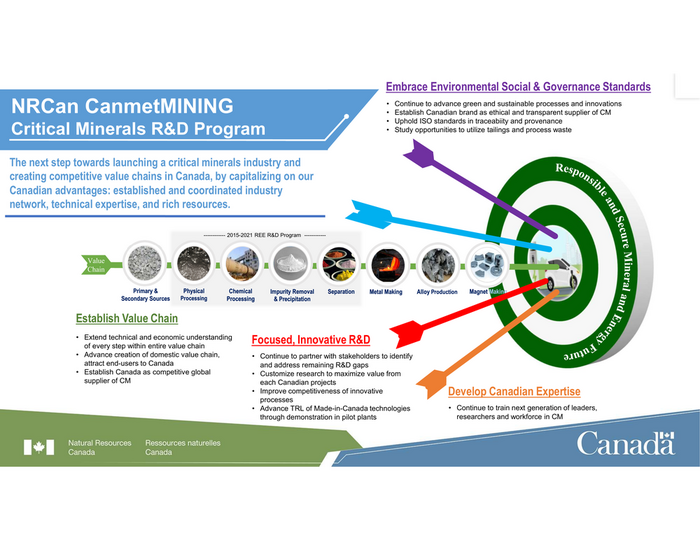

Embrace Environmental Social & Governance Standards NRCan CanmetMINING • • Continue to advance green and sustainable processes and innovations Establish Canadian brand as ethical and transparent supplier of CM • Uphold ISO standards in traceabiity and provenance Critical Minerals R&D Program • Study opportunities to utilize tailings and process waste The next step towards launching a critical minerals industry and creating competitive value chains in Canada, by capitalizing on our Canadian advantages: established and coordinated industry network, technical expertise, and rich resources. ------------ 2015-2021 REE R&D Program ------------ Value Chain Primary & Physical Chemical Impurity Removal Separation Metal Making Alloy Production Magnet Making Secondary Sources Processing Processing & Precipitation Establish Value Chain • Extend technical and economic understanding of every step within entire value chain Focused, Innovative R&D • Advance creation of domestic value chain, • Continue to partner with stakeholders to identify attract end-users to Canada and address remaining R&D gaps • Establish Canada as competitive global • Customize research to maximize value from supplier of CM each Canadian projects • Improve competitiveness of innovative Develop Canadian Expertise processes • Advance TRL of Made-in-Canada technologies • Continue to train next generation of leaders, through demonstration in pilot plants researchers and workforce in CM

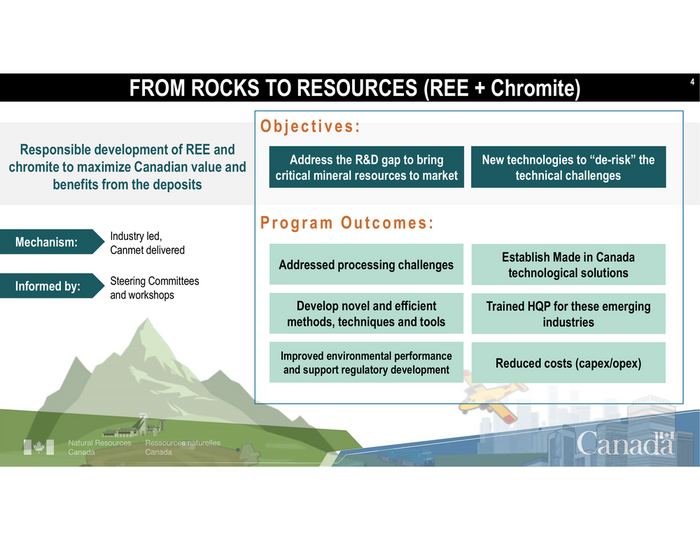

FROM ROCKS TO RESOURCES (REE + Chromite) 4 Objectives: Responsible development of REE and Address the R&D gap to bring New technologies to “de-risk” the chromite to maximize Canadian value and critical mineral resources to market technical challenges benefits from the deposits Program Outcomes: Industry led, Mechanism: Canmet delivered Establish Made in Canada Addressed processing challenges technological solutions Steering Committees Informed by: and workshops Develop novel and efficient Trained HQP for these emerging methods, techniques and tools industries Improved environmental performance and support regulatory development Reduced costs (capex/opex)

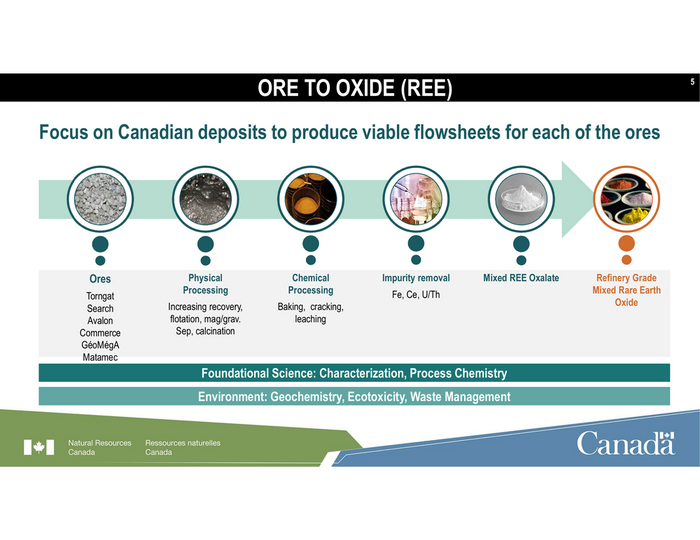

ORE TO OXIDE (REE) 5 Focus on Canadian deposits to produce viable flowsheets for each of the ores Ores Physical Chemical Impurity removal Mixed REE Oxalate Refinery Grade Processing Processing Fe, Ce, U/Th Mixed Rare Earth Torngat Increasing recovery, Baking, cracking, Oxide Search Avalon flotation, mag/grav. leaching Commerce Sep, calcination GéoMégA Matamec Foundational Science: Characterization, Process Chemistry Environment: Geochemistry, Ecotoxicity, Waste Management

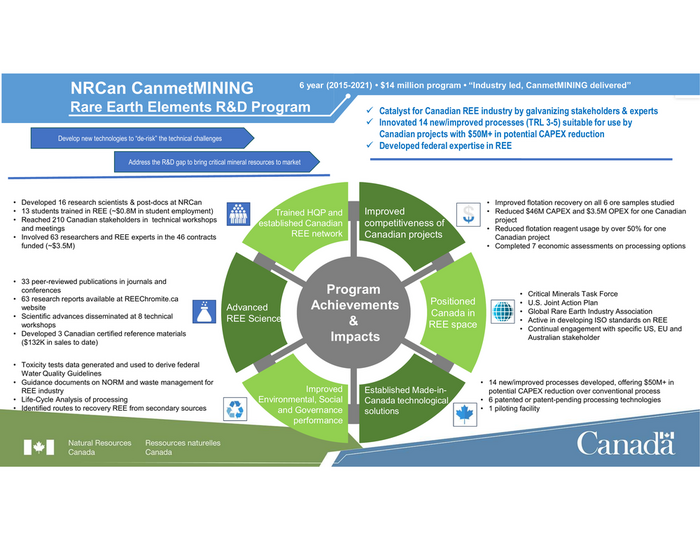

NRCan CanmetMINING 6 year (2015-2021) • $14 million program • “Industry led, CanmetMINING delivered” Rare Earth Elements R&D Program Catalyst for Canadian REE industry by galvanizing stakeholders & experts Innovated 14 new/improved processes (TRL 3-5) suitable for use by Develop new technologies to “de-risk” the technical challenges Canadian projects with $50M+ in potential CAPEX reduction Developed federal expertise in REE Address the R&D gap to bring critical mineral resources to market • Developed 16 research scientists & post-docs at NRCan • Improved flotation recovery on all 6 ore samples studied • 13 students trained in REE (~$0.8M in student employment) Trained HQP and Improved • Reduced $46M CAPEX and $3.5M OPEX for one Canadian • Reached 210 Canadian stakeholders in technical workshops project established Canadian competitiveness of and meetings • Reduced flotation reagent usage by over 50% for one • Involved 63 researchers and REE experts in the 46 contracts REE network Canadian projects Canadian project funded (~$3.5M) • Completed 7 economic assessments on processing options • 33 peer-reviewed publications in journals and conferences Program • Critical Minerals Task Force • 63 research reports available at REEChromite.ca Positioned website Advanced Achievements • • U.S. Joint Action Plan Global Rare Earth Industry Association • Scientific advances disseminated at 8 technical Canada in REE Science & • Active in developing ISO standards on REE workshops REE space • Continual engagement with specific US, EU and • Developed 3 Canadian certified reference materials ($132K in sales to date) Impacts Australian stakeholder • Toxicity tests data generated and used to derive federal Water Quality Guidelines • Guidance documents on NORM and waste management for • 14 new/improved processes developed, offering $50M+ in REE industry Improved Established Made-in- potential CAPEX reduction over conventional process • Life-Cycle Analysis of processing Environmental, Social Canada technological • 6 patented or patent-pending processing technologies • Identified routes to recovery REE from secondary sources and Governance solutions • 1 piloting facility performance

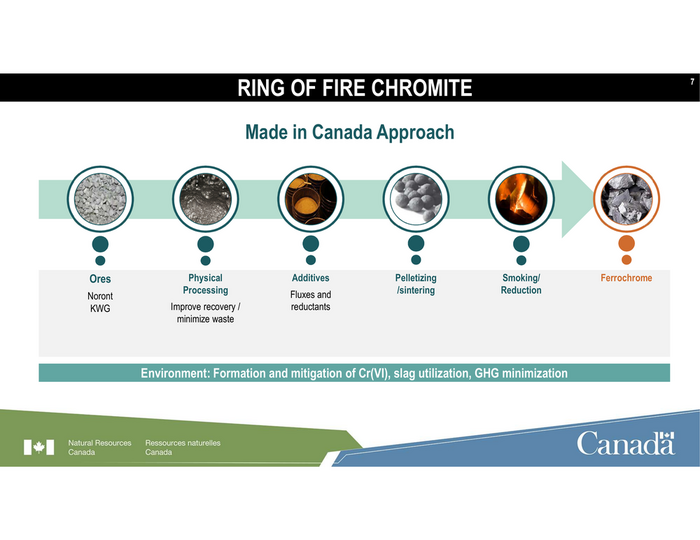

RING OF FIRE CHROMITE 7 Made in Canada Approach Ores Physical Additives Pelletizing Smoking/ Ferrochrome Processing Fluxes and /sintering Reduction Noront KWG Improve recovery / reductants minimize waste Environment: Formation and mitigation of Cr(VI), slag utilization, GHG minimization

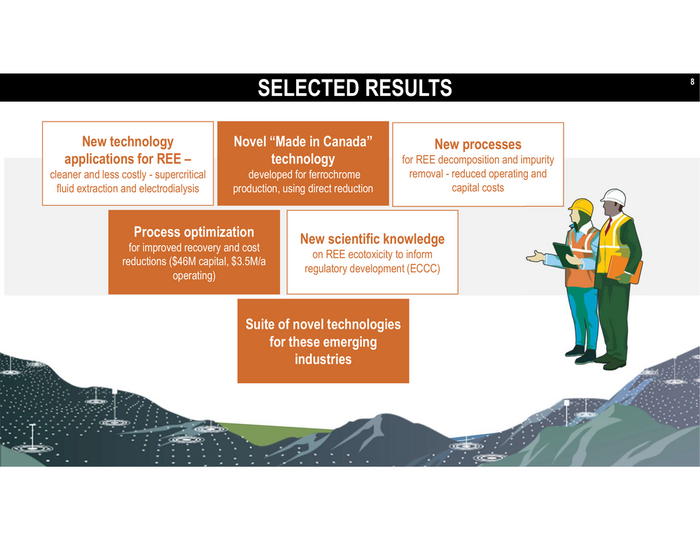

SELECTED RESULTS 8 New technology Novel “Made in Canada” New processes applications for REE – technology for REE decomposition and impurity cleaner and less costly - supercritical developed for ferrochrome removal - reduced operating and fluid extraction and electrodialysis production, using direct reduction capital costs Process optimization New scientific knowledge for improved recovery and cost on REE ecotoxicity to inform reductions ($46M capital, $3.5M/a regulatory development (ECCC) operating) Suite of novel technologies for these emerging industries

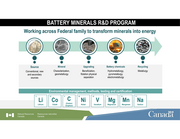

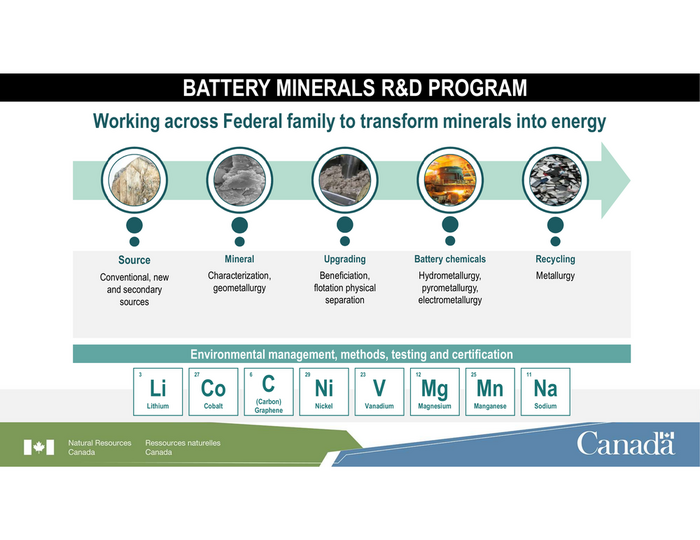

BATTERY MINERALS R&D PROGRAM Working across Federal family to transform minerals into energy Source Mineral Upgrading Battery chemicals Recycling Conventional, new Characterization, Beneficiation, Hydrometallurgy, Metallurgy and secondary geometallurgy flotation physical pyrometallurgy, sources separation electrometallurgy Environmental management, methods, testing and certification C 3 27 6 29 23 12 25 11 Li Co (Carbon) Ni V Mg Mn Na Lithium Cobalt Nickel Vanadium Magnesium Manganese Sodium Graphene

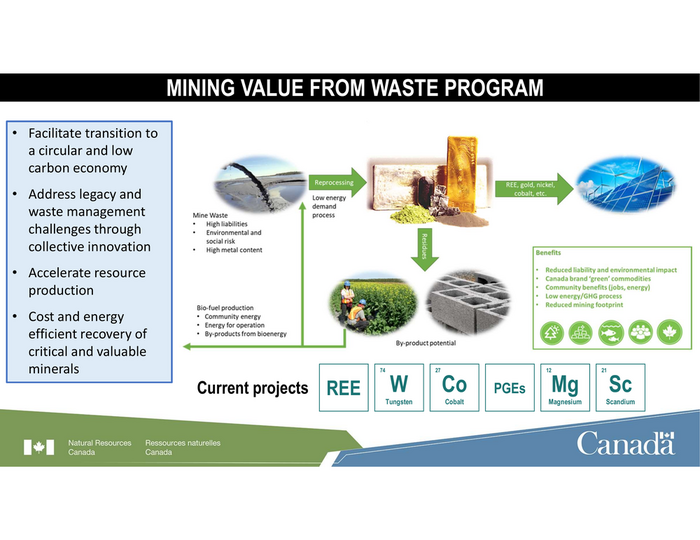

MINING VALUE FROM WASTE PROGRAM • Facilitate transition to a circular and low carbon economy • Address legacy and waste management challenges through collective innovation • Accelerate resource production • Cost and energy efficient recovery of critical and valuable minerals 74 27 12 21 Current projects REE W Co PGEs Mg Sc Tungsten Cobalt Magnesium Scandium